Machining and Turning

Bar-Pulling

the ability to cut bar stock parts, stack them, and pull the next part to be cut all automatically without the need of an operator. This reduces lead times, increases production, and decreases labor cost when producing these parts.

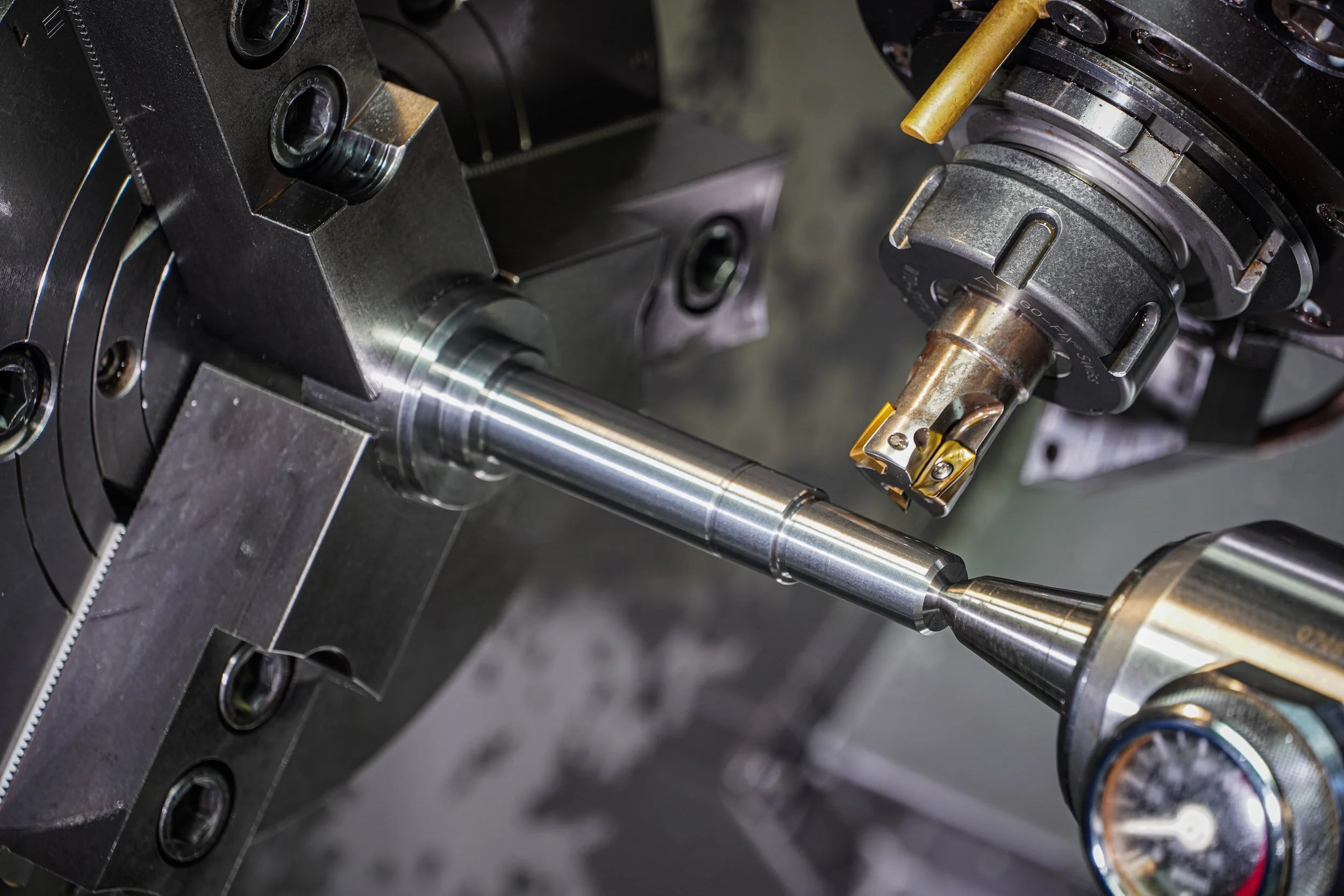

Live Tooling

With live tooling, we are able to take two process parts that would need to be milled after the lathe process and produce and finish them all under that lathe operation. This includes adding holes to the side of the part, creating flats on a turned part, and threading turned parts from the side location.

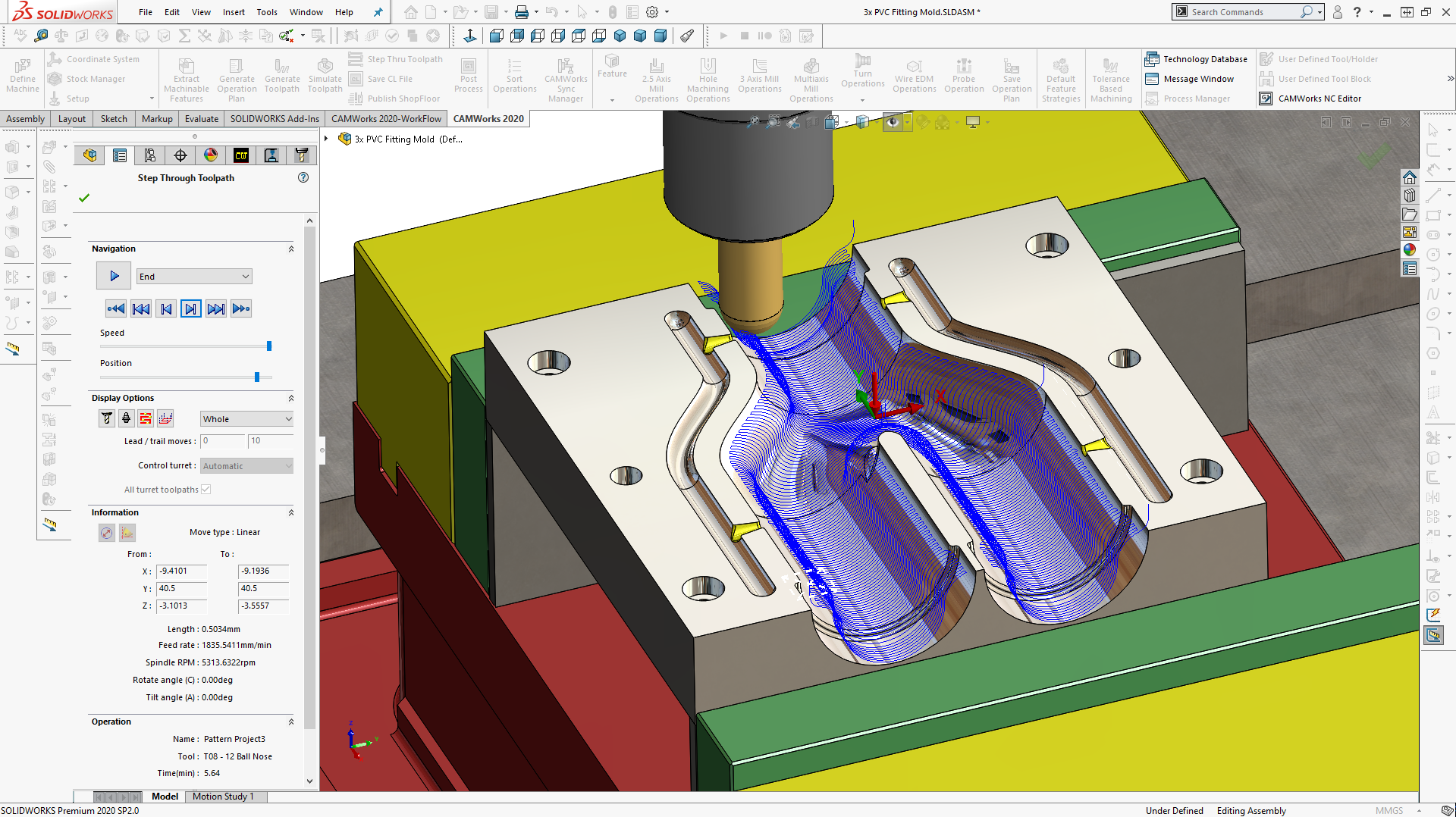

Cam Works Software

With this software, we are able to write complex programs from generated code created from this software. This helps to reduce setup time when programming new parts as well as decrease the chances of mistakes when writing your own G-code.

Capabilities

since we have both lathe and milling machines we can virtually do most machining work.

The lathe can get up to RPm. The Mills can get up to RPM. WE have the ability to hold up to tools on our mills and tools on our lathes. We can do most metals on the market.